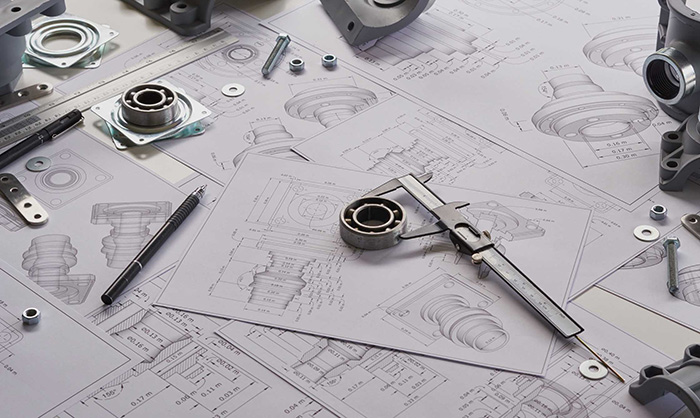

CNC Machine Design Principles You Need to Know

Designing for CNC machining requires attention to detail and optimization of part geometry to reduce production costs and meet the desired outcome. Knowing the principles of CNC machine design is essential in achieving this goal, and incorporating these tips can help you make the most out of your CNC machining project. It can help you reduce machining costs, create better-quality parts, and bring your ideas to life with precision.

Cost-effectively manufacturing parts with good quality is the main focus when designing for CNC machines. Design for Machinability principles are essential to achieve this and also ensure that functional design requirements are still met. This article provides extensive tips and guidelines on how to optimize your design so you can save costs in CNC machining. We will uncover what increases the cost in CNC machining and provide proven design tips that you can use to drastically reduce production costs.

Cost of CNC Machining and Factors That Influence It

- The Machining Time

The quote for CNC machined parts is determined by the following factors.

CNC machining costs are largely determined by machining time, with the price rising for longer amounts of machine time. This is especially the case for large-scale production runs; design mistakes that slow down the process can significantly impact economies of scale.

- The Set-up

CNC machining involves costly start-up costs that are primarily related to CAD file preparation and process planning, especially for smaller production volumes. Fortunately, they are fixed regardless of the output. Manufacturers can leverage economies of scale and reduce the cost per unit by increasing their volume, provided that the design and surface finish remain applicable to scaling.

- Requirement of manufacturing

CNC machining can be an expensive process depending on the level of complexity needed for a particular product. The cost associated with CNC machining consists of tooling expenses, labor costs, and the time it takes to produce the parts. Factors such as close tolerances, thin walls, and complex features will increase costs due to additional tooling, quality control measures and longer processing times.

- Material Cost

Cost of CNC machining mainly depends on the bulk material and its suitability for the process. To keep costs low, it is important to optimize the design being machined and select the most suitable material. Developing a thorough understanding of available materials and their properties can also help to reduce expenses.

Tips To Reduce CNC Machining Cost

- Adding a radius to an internal vertical edge

CNC machining is an effective, precise way of cutting materials. One way to reduce the cost while still having an accurate cut is to use a tool with a smaller diameter. Though this will take longer as multiple passes at a lower speed are needed due to smaller tools cutting material more slowly, overall costs can be kept down.

One of the best ways to reduce the cost of CNC machining is to design a part with larger corner radii than the radius of the tool being used. This minimizes loading on the tool, allowing for faster speeds and reduced costs.

Another useful technique is to replace internal circular radii with undercuts that provide sharp corners that require less machining time. This simple step can dramatically reduce the cost of CNC machining while still producing high-quality parts.

- Topping cavity expansion and limiting the depth of cavities

CNC machining is a cost-efficient option for cutting complex shapes, however it can become costly when producing deep cavities due to the amount of material needed to be removed in the process.

Due to the limited length of CNC cutting tools, they are most effective when used for cavities that have a depth less than two to three times their diameter. For instance, a 10mm milling tool can safely carve out cavities that are no deeper than 20mm. Deeper cavities require specialized CNC machines or tooling in order to be done efficiently and cost-effectively.

- Increasing the thickness of thin walls

If a thicker section is being machined, it is generally more stable and cost effective. When machining thin sections however, multiple passes need to be done at lower cutting depths in order to avoid any fractures or deformations. Also, these thinner features are very prone to vibration and require extra time for accurate results.

For metal parts, it is important to have walls thicker than 0.8mm in order for the part to be machined correctly; thicker walls are even better. For plastic manufactured parts, make sure that the wall thickness is 1.5mm or above for successful machining of the part.

When designing parts that require holes and threads located close to a part’s edge, it’s important to keep this in mind as it can affect the successful machining of the part.

- Limiting the depth of threads

Including threads that are longer than necessary can increase the cost of CNC parts because special tooling may be required. Threads longer than 1.5 times the diameter of the hole do not enhance a connection’s strength.

Design threads with a maximum length of up to three times the hole diameter. For threads in blind holes, add at least half of the diameter of the unthreaded length at the bottom of the hole.

- Standard hole sizes

Holes can be CNC-machined quickly and to great accuracy using standard drill bits. For non-standard sizes, an extra machining step is required, which drives up cost.

When possible, use through holes instead of blind holes because they are easier to machine.

When designing holes for CNC machining, the diameter must be incremented within 0.1mm increments up to 10mm, after which it should be incremented by 0.5mm.

This CNC machining technique uses a variety of cutting tools, such as lathes and milling machines, to fashion intricate parts out of solid materials at high speed. It is often used in the production of metal components, but can also be applied to plastic, wood and other materials. When designing for CNC machining in inches, either referring to fractions from a table or use conventional fractions of an inch are recommended for accuracy.

- Carefully specifying tolerances

Typically, when a specific tolerance is not outlined in the technical drawing of a component, standard tolerances (e.g. ± 0.125mm) are employed unless absolutely necessary to meet more exacting requirements. This is usually sufficient for most non-critical parts and features.

it is important to only define tighter tolerances when absolutely necessary. When possible, choose one datum (e. g. the cross-section of two edges) as a reference for all dimensions with tolerances to help keep your parts consistent and accurate.

Using Geometric Dimensioning and Tolerancing (GD&T) in technical drawings when creating these components can help to reduce production costs while still producing parts with high accuracy. GD&T specifies features such as flatness, straightness, circularity, and true position, though it requires a knowledgeable engineer for proper implementation.

- Less machine setups

By designing parts that can be machined in as few setups as possible, CNC machining can greatly reduce costs and speed up production time. Ideally, parts should be designed to only require one setup, however for certain parts with blind holes on both sides (that require them to be rotated for proper access), two setups may be needed.

CNC machining enables the mass production of complex shapes without the need for manual steps such as rotating or repositioning. Furthermore, the process can create intricate geometries without the need for custom fixtures, and even create highly complicated shapes using multi-axis CNC systems.

If you have a part that is too large or complex for one CNC machining setup, consider breaking it down into multiple geometries that can be finished in one setup and then joined together either by welding or bolting. Deep pockets are especially well-suited for this kind of approach.

- Avoiding small features

CNC machining allows for precision machining and is well-suited for producing parts with complex shapes or a high width-to-height aspect ratio. Unfortunately, such parts can be prone to vibration and thus difficult to machine accurately.

CNC machining is a process that can create complex designs with a width-to-height aspect ratio of less than four, including features that require bracing support or connecting to walls for improved stiffness.

- Avoiding text on the surface

Although it is possible to add text to the surface of a CNC-machined part, it can drive up cost as it requires additional machining steps. A more economical option for adding text on the surface is by using surface finishing methods such as silk screening or painting.

- Improving the machinability of metals

CNC machining is a manufacturing process used to cut and shape materials of varying hardness. The higher the machinability of the material, the faster and cheaper it can be CNC machined. Physical properties such as ductility and softness play an important role in determining how easy a material is to machine. Generally, softer, more ductile materials are less expensive and easier to work with than harder materials.